Feature

Q1: What are the characteristics of the Yellow Round Valve

A: The yellow round valve has a stable structure, clear opening and closing mechanism, uniform oil flow, and a conspicuous color for easy identification and operation. It is commonly used in commercial and industrial oil packaging.

Q2: What are the differences between a round valve and a duckbill valve?

A: Round valves typically require manual opening and closing, allowing for precise control of the oil flow; duckbill valves have a self-sealing structure. Round valves are more suitable for applications requiring frequent opening and closing or connection to external dispensing equipment.

Q3: Does this valve support connection to hoses or dispensing equipment?

A: Yes, the round valve is designed for easy connection to hoses, pumps, or semi-automatic dispensing devices, suitable for filling, dispensing, and downstream applications.

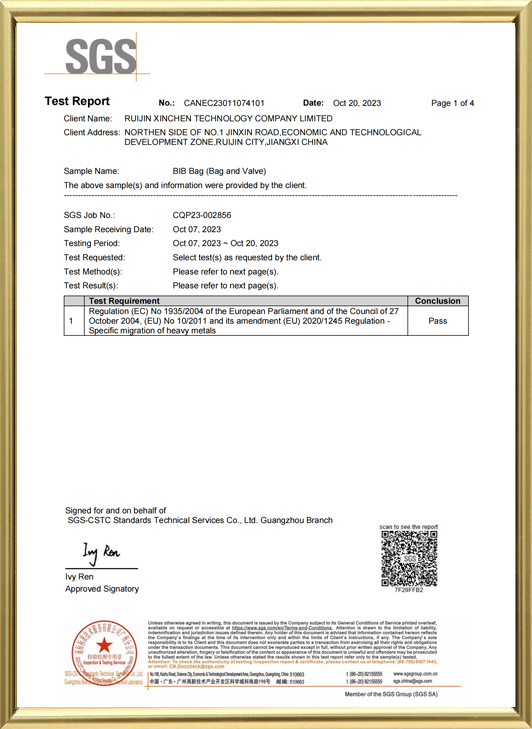

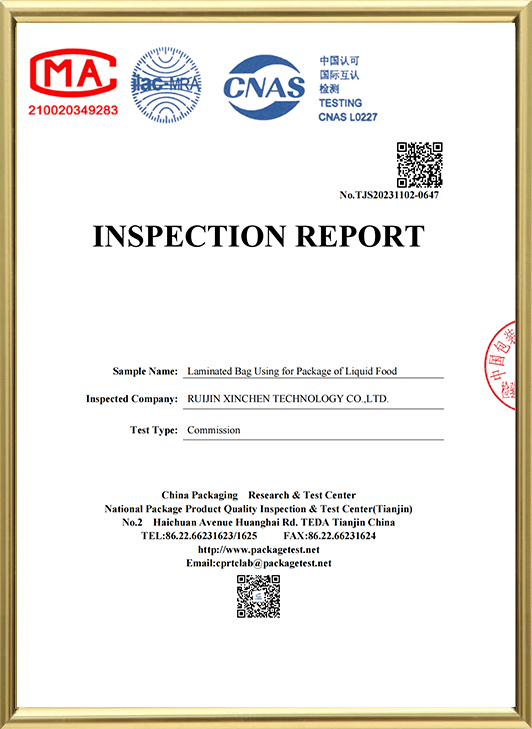

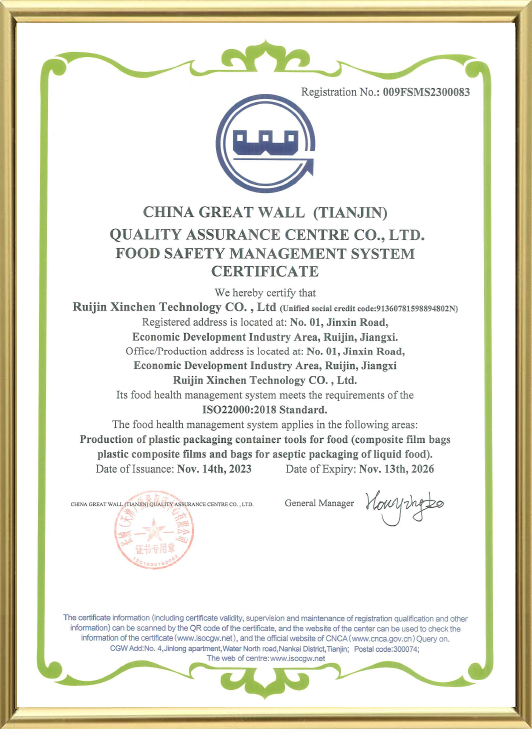

Q4: Is the Flexi Bag made of food-grade materials?

A: Yes, both the bag body and the valve are made of food-grade materials, meeting the safety requirements for edible oil packaging.

Q5: Can it be used with an outer box to form a Bag-in-Box system?

A: Yes, the Flexi Bag can be used independently or combined with a corrugated cardboard box to form a Bag-in-Box structure, facilitating transportation and stacking.

English

English русский

русский